Our services

What we do

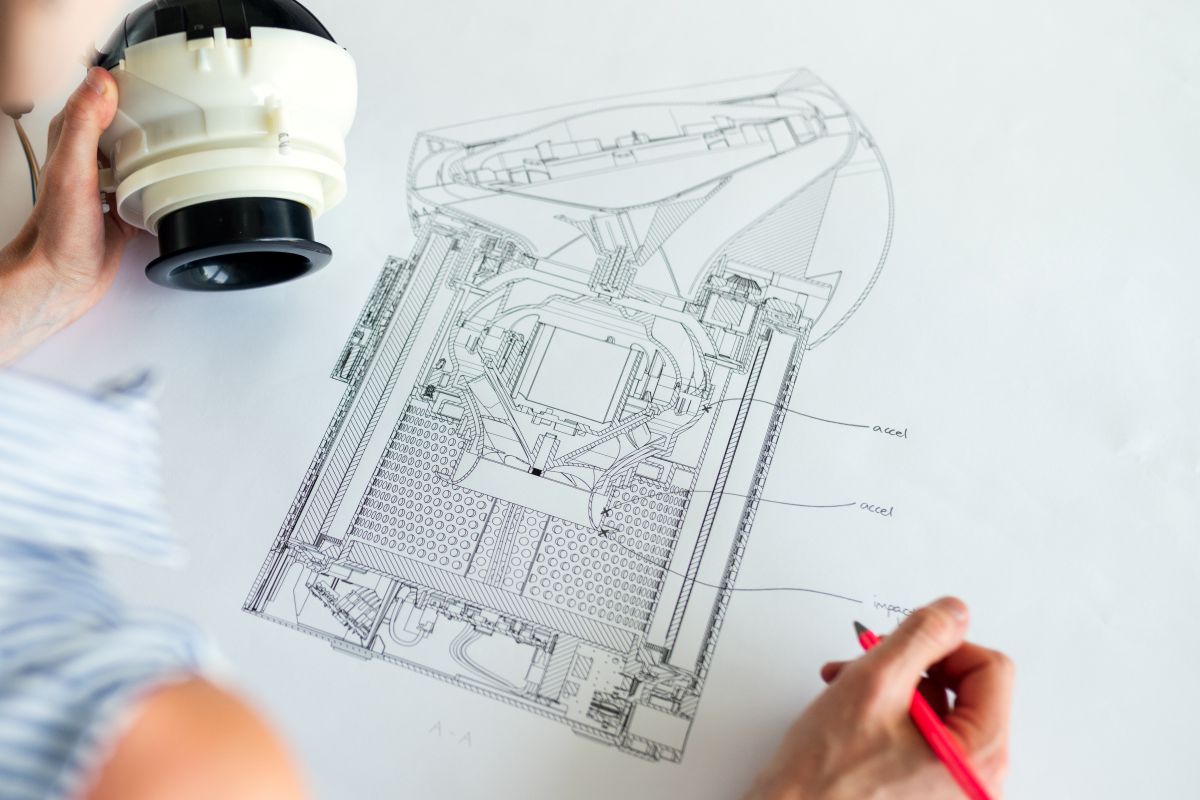

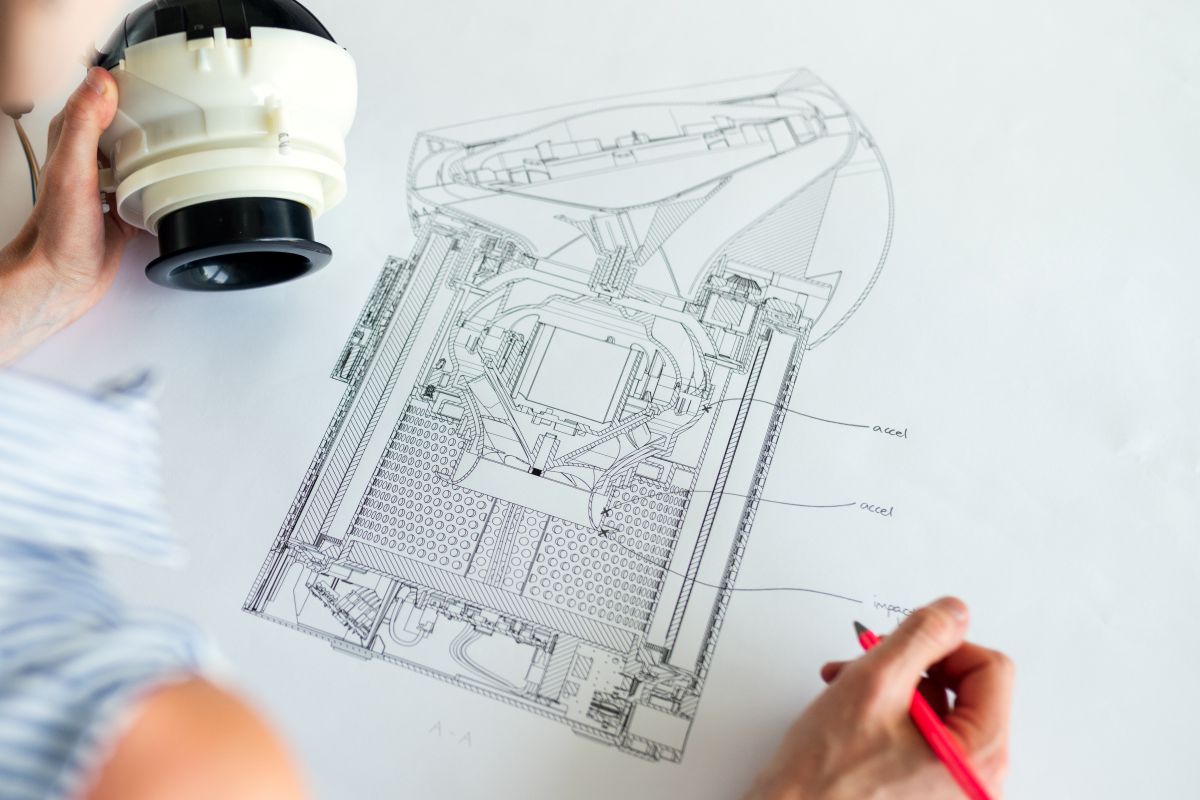

Product design and concept sketching

Engineering drawings are of utmost important when the dimensions of your product are being recorded. This enables the manufacturing department to produce a product of high dimensional accuracy according to the client’s specifications. Hardcopy and digital forms of drawings are available with for copyright purposes and to ensure clients have legal proof of their designs with all detailed specifications. We also offer you the convenience of branding and signage to personalize products. All buttons, ports, displays, or switches are designed with the customer and user in mind, so we are confident the enclosure is easy to use, and fits the customers every requirement.

Reverse engineering

Reverse engineering is done for products with standard components; the dimensions of the standard components are recorded to an accuracy of 0.2 mm to ensure a product is produced with a perfect fit.

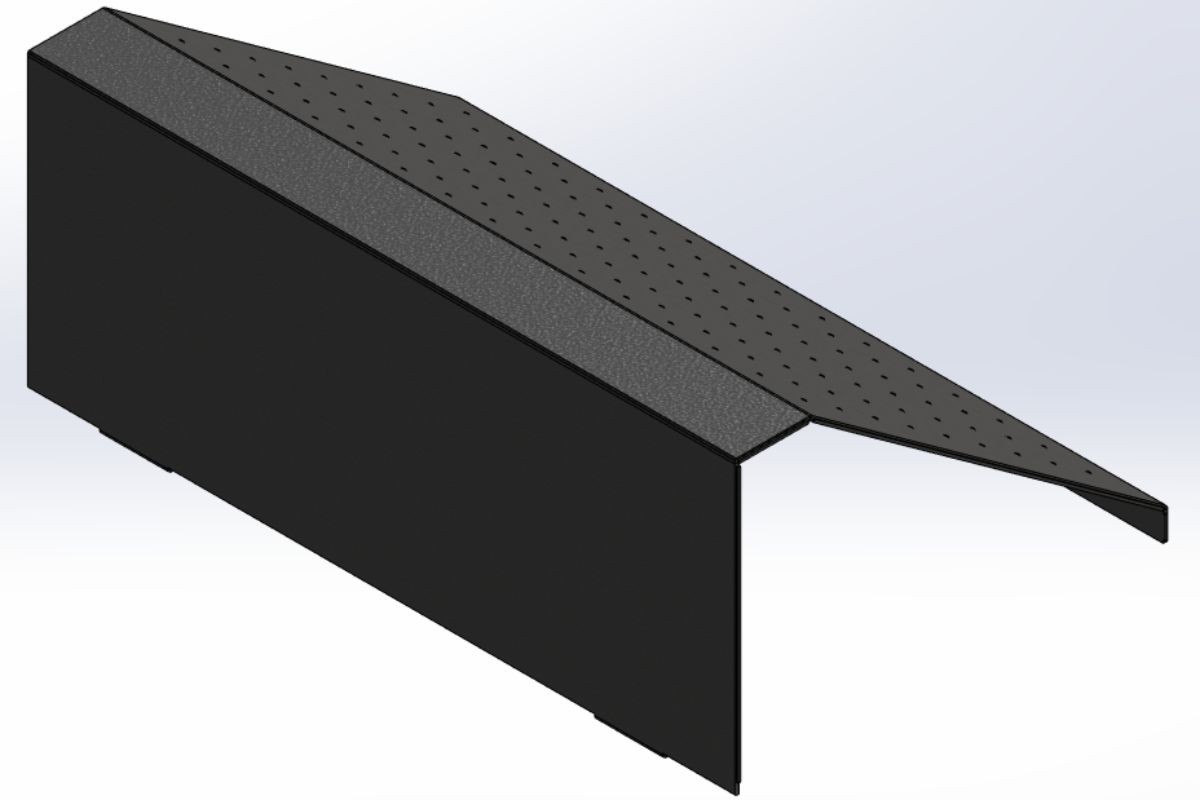

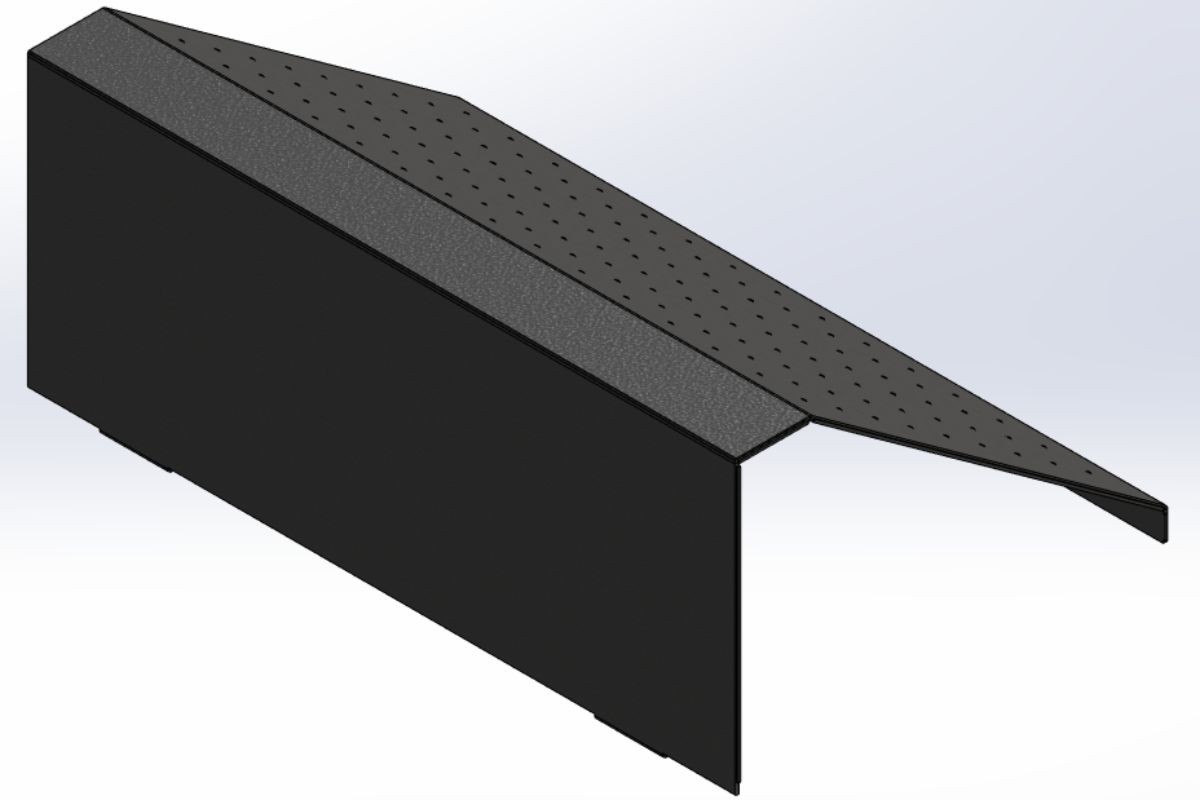

Rendering and CAD modelling

Rendering and CAD modelling is used to model the designed product and render it in a real-world environment. With added texture a virtual image can be captured of the designed product to show the customer what it will look like when manufactured. Renders can be used when large images are required such as is needed for advertising or presentation purposes rather than taking a standard photograph. The renders can be virtually projected into a studio or real-world environment using design programs rather than paying extra money to hire a photographer and studio to shoot your product.

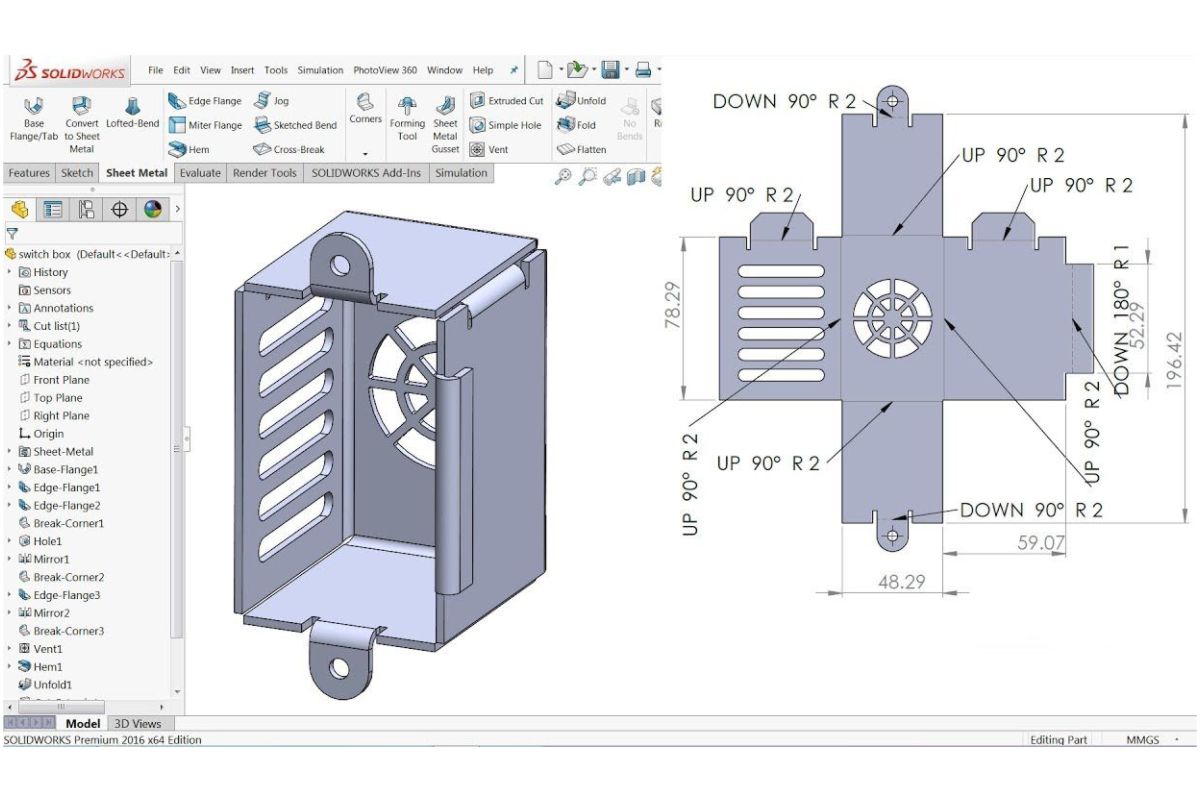

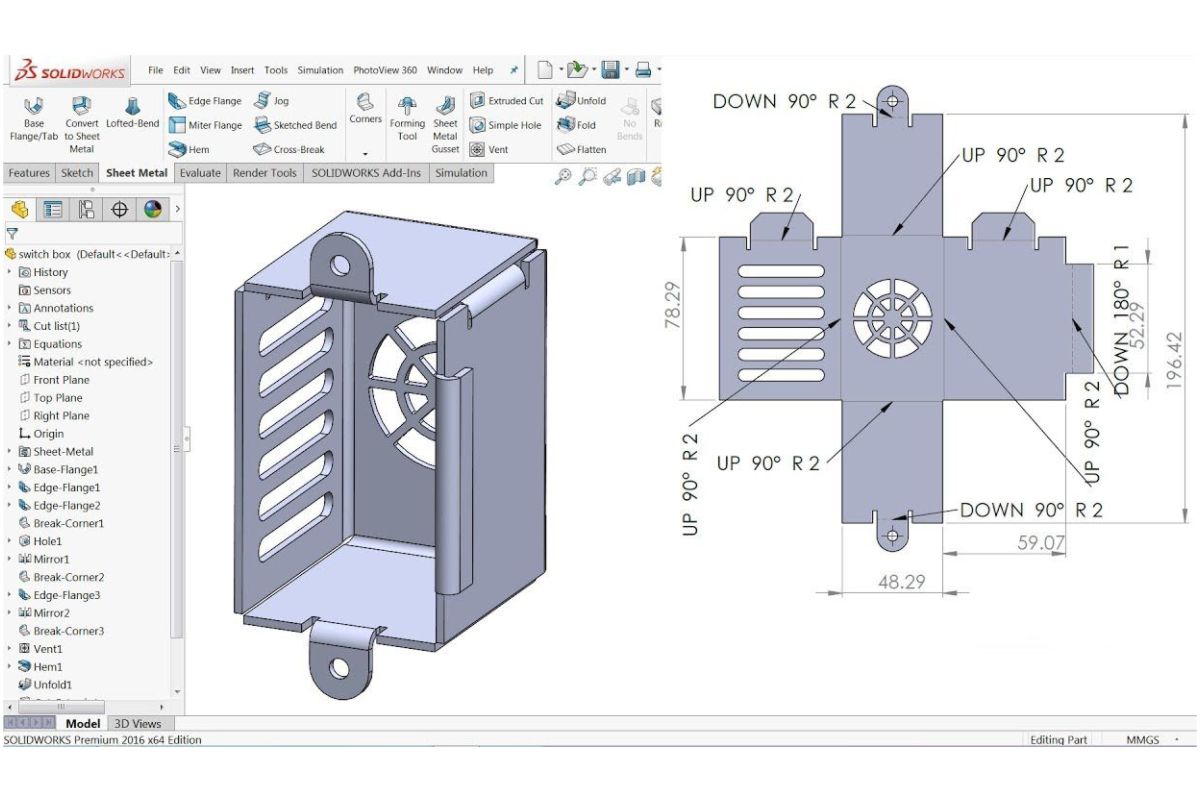

Engineering drawings

Engineering drawings are of utmost important when the dimensions of your product are being recorded. This enables the manufacturing department to produce a product of high dimensional accuracy according to the client’s specifications. Hardcopy and digital forms of drawings are available with for copyright purposes and to ensure clients have legal proof of their designs with all detailed specifications. We also offer you the convenience of branding and signage to personalize products. All buttons, ports, displays, or switches are designed with the customer and user in mind, so we are confident the enclosure is easy to use, and fits the customers every requirement.

ABS plastic custom enclosures

We create different types of plastic enclosures that range from small and simple to large and complex. With over 10+ years manufacturing using this unique process we have the knowledge and experience to deliver standard plastic enclosures that meet and exceed customer expectations. We manufacture and design customized enclosures according to the client’s design requirements. We work closely with our clients to achieve the most functional and suitable product according to the design specifications needed.

Whether it is for a small enclosure or a large enclosure for your electronic components. CSE TECH has the capability to deliver a quality product to make electronic projects a reality.

For the plastic project boxes, we offer a wide variety of ABS material thicknesses as well as any different size enclosures.

Materials thicknesses variety from 3mm, 4mm, and 6mm.

Our plastic housings usually come in black, white, light grey, or dark grey depends on materials availability.

All plastic enclosures are designed and cut as flat patterns and machined only on one side, this cuts out opposite site machining and cuts back on the cost of labour per item. We are able to add tongues and grooves via sawing and table router to ensure easy assembly. A single qualified person runs multiple machines which guarantees uniformity in workmanship and crafting and also reduces labour expenses. Sheets are cut and milled with precision by Computer Numerical Controlled (CNC) machines with a tolerance of +/- 0.2mm. Tabs are designed to provide rigid holding points during machining and are easily broken out after the product is complete.

A bending table is used to bend and form plastic parts to specific angles or make custom bends for unique custom enclosures. Bends can assist the customer during assembly. The following angles can be achieved: 115° up, maximum standard bend; 45° down, maximum reverse bend; inside bend radius square for 90° bend; 6mm bends tend to warp edges, a 1mm chamfer hides this.

Chamfering and lip edging of plastic parts is available for assembly and completion processes. Chamfers, tongues and grooves can be made. A 0.5mm chamfer on the edge of the tongue can be made to create a cosmetic seam and hide the heat deflection caused at the bend site.

A solvent is used to melt respective pieces together for a seamless finish without compromising strength. By designing the product in such a way as to avoid placing solvent join at a site of high tension.

1K and 2K spray painting

1K and 2K Spray Paint can be done in any colour.

1K paint is less hard-wearing than the 2K alternative. 1K paint is more suitable for items and areas less prone to potential scratches and general wear and tear such as higher cladding panels on a building that do not frequently come into contact with day to day touching and potential damage. 1K paint has a faster drying time compared to 2K paint and will air dry. 1K paints typically dry’s faster than 2K paints.

2K paint provides a harder wearing coat more suitable for surfaces that may come into contact with day-to-day use and heavy access areas. 2K means an activator is required to dry/ cure, sometimes referred to as a hardener. The hardener works by chemically reacting with a catalyst which sets hard to form a very tough finish.

1K and 2K paints have a heat resistant, between 160 – 190 degrees Celsius.

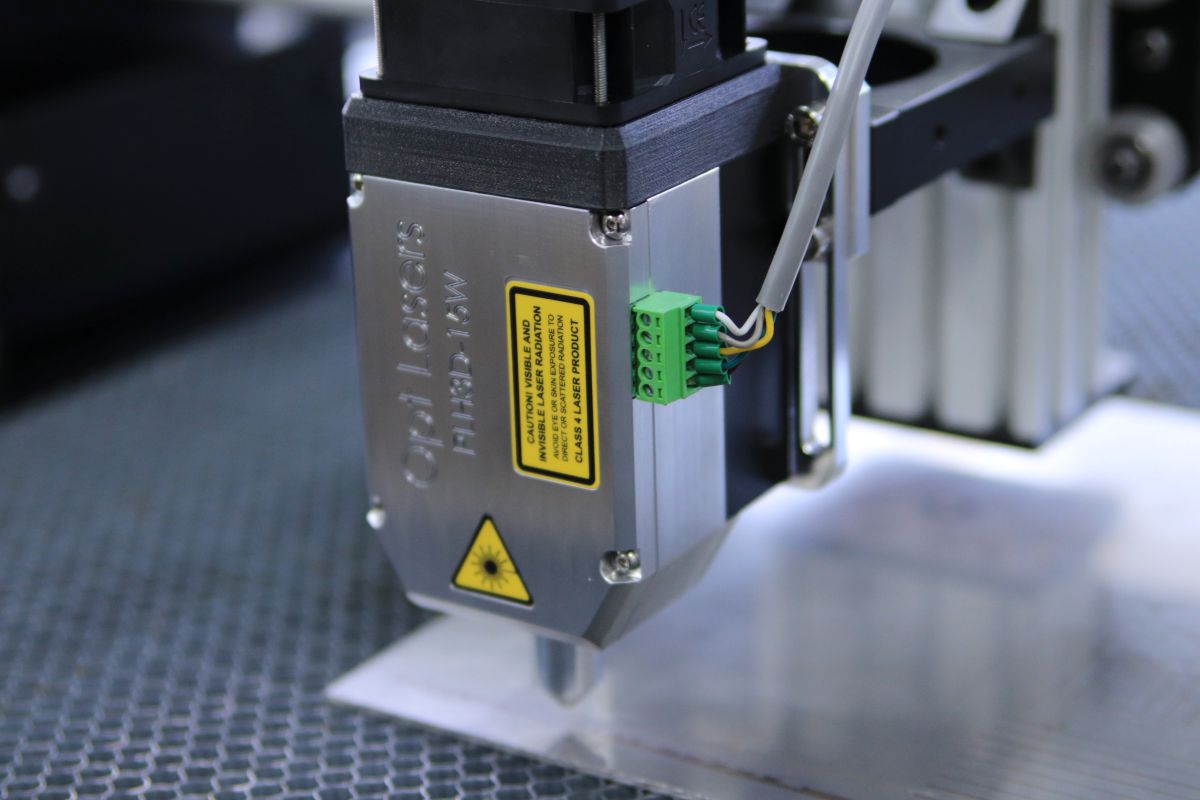

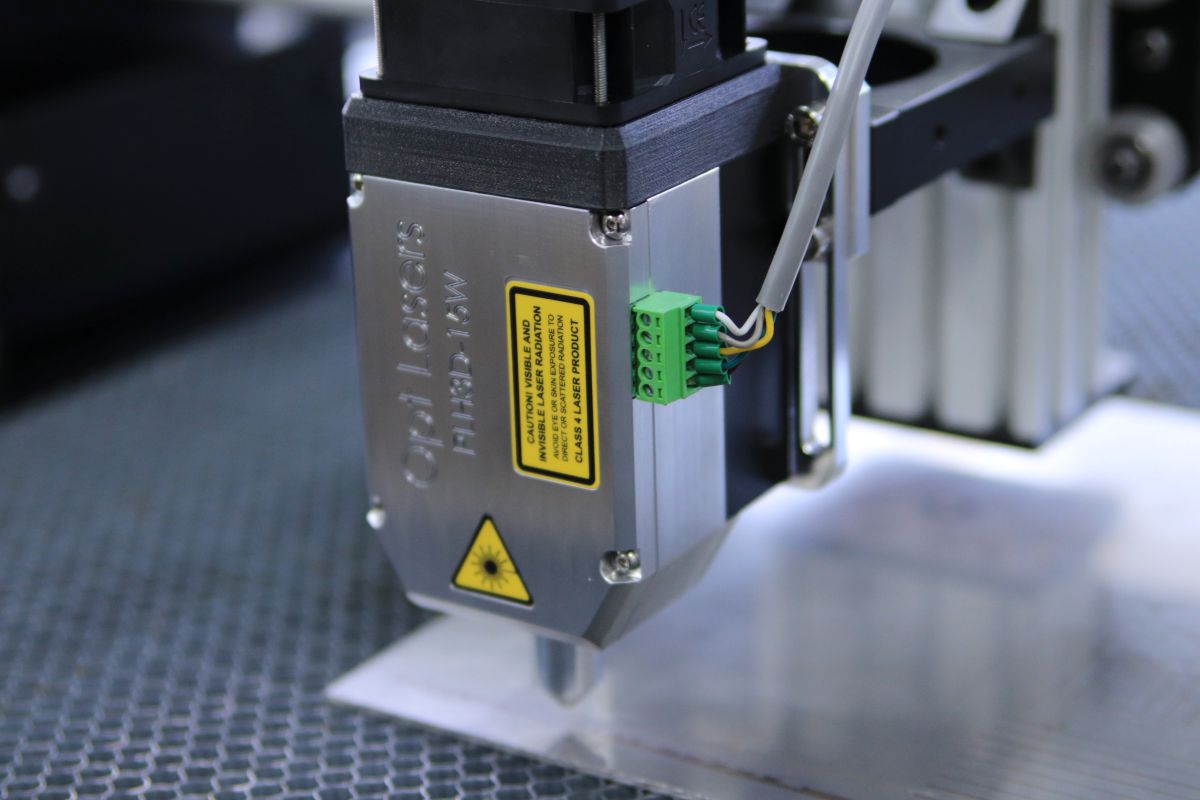

Laser cutting

Laser cutting is a technology that uses a laser to cut materials up to 15mm thick and is typically used for industrial manufacturing applications. Laser cutting works by directing the output of a high-power laser most commonly through optics. Cuts MDF Wood, Acrylics, Cardboard, Foam, Cork, variety of Materials.

Laser engraving

Laser engraving, which is a subset of laser marking, is the practice of using lasers to engrave an object. This is used for etching bar codes onto items or personalising certain items.

Laser marking

This is like engraving in that a mark is made but the difference being that the mark is only surface level, while engraving from laser engraving has much more depth.

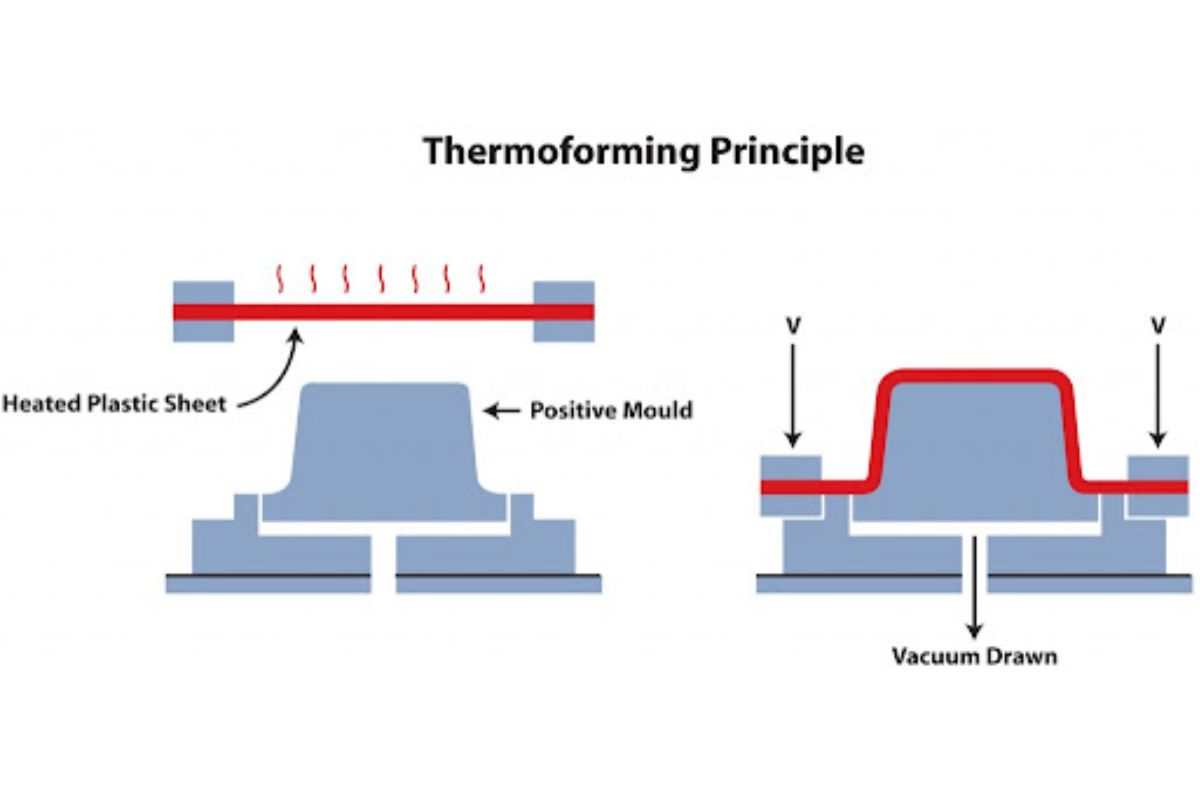

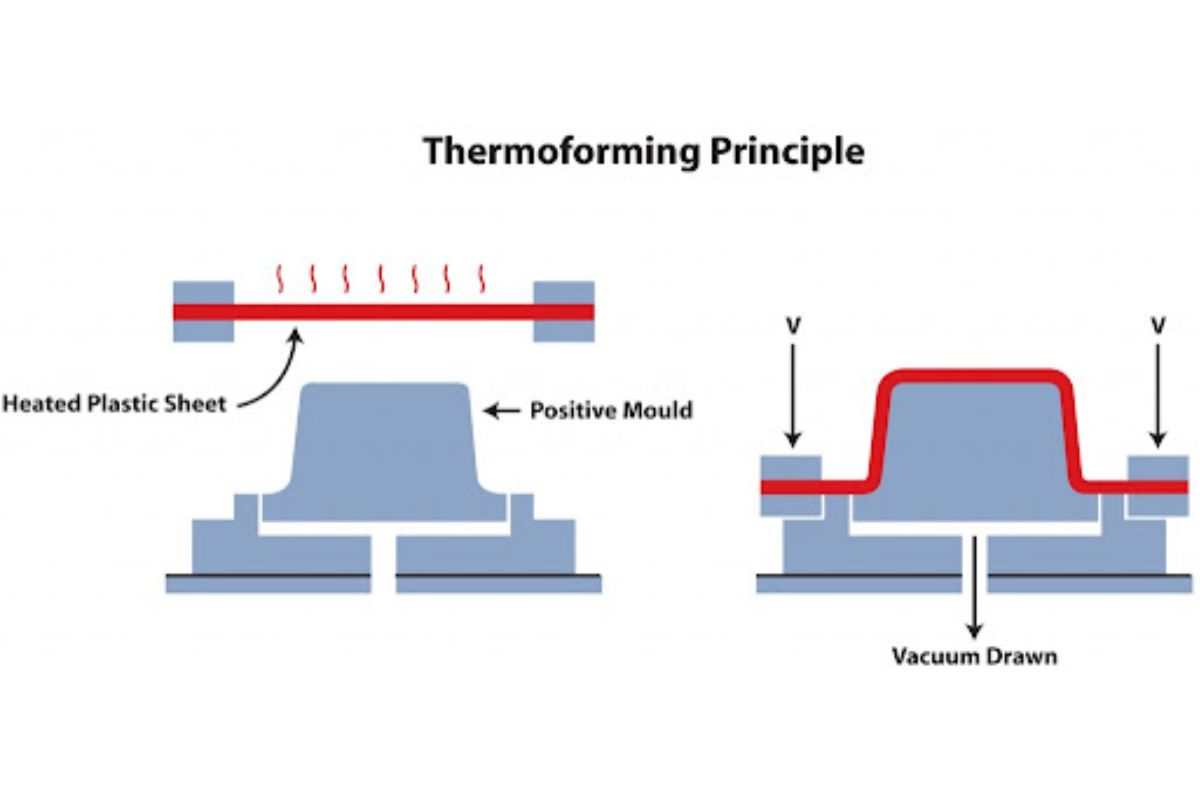

Vacuum forming (Thermoforming Principle)

Vacuum forming is a simplified version of thermoforming, where a sheet of plastic is heated to a forming temperature, stretched onto a single surface mold, and forced against the mold by a vacuum. This process can be used to form plastic into permanent objects such as turnpike signs and protective covers.

Forming bed: 200 x 200mm

Draw depth: 130mm

3D printing

3D printing uses computer-aided design (CAD) to create three-dimensional objects through a layering method. Sometimes referred to as additive manufacturing, 3D printing involves layering materials, like plastics, composites or bio-materials to create objects that range in shape, size, rigidity and colour.

* Build volume: 450 x 450 x 470mm

* Filament diameter: 1.75mm

* Compatible filaments: PLA, ABS, PETG, TPU, Wood, Nylon

* Compatible file format: STL, OBJ, AMF

* Printing resolution: 0.1mm

UV printing

Is a unique method of digital printing utilising ultraviolet (UV) light to dry or cure ink, adhesives, or coatings almost as soon as it’s hit the paper, or aluminium, foam board or acrylic – in fact, as long as it fits in the printer, the technique can be used to print on almost anything.

While there are many ways to print, few match UV’s speed-to-market, environmental impact, and colour quality. It cures fast, its high quality, it’s durable and it’s flexible.

What we do

Product design and concept sketching

Engineering drawings are of utmost important when the dimensions of your product are being recorded. This enables the manufacturing department to produce a product of high dimensional accuracy according to the client’s specifications. Hardcopy and digital forms of drawings are available with for copyright purposes and to ensure clients have legal proof of their designs with all detailed specifications. We also offer you the convenience of branding and signage to personalize products. All buttons, ports, displays, or switches are designed with the customer and user in mind, so we are confident the enclosure is easy to use, and fits the customers every requirement.

Reverse engineering

Reverse engineering is done for products with standard components; the dimensions of the standard components are recorded to an accuracy of 0.2 mm to ensure a product is produced with a perfect fit.

Rendering and CAD modelling

Rendering and CAD modelling is used to model the designed product and render it in a real-world environment. With added texture a virtual image can be captured of the designed product to show the customer what it will look like when manufactured. Renders can be used when large images are required such as is needed for advertising or presentation purposes rather than taking a standard photograph. The renders can be virtually projected into a studio or real-world environment using design programs rather than paying extra money to hire a photographer and studio to shoot your product.

Engineering drawings

Engineering drawings are of utmost important when the dimensions of your product are being recorded. This enables the manufacturing department to produce a product of high dimensional accuracy according to the client’s specifications. Hardcopy and digital forms of drawings are available with for copyright purposes and to ensure clients have legal proof of their designs with all detailed specifications. We also offer you the convenience of branding and signage to personalize products. All buttons, ports, displays, or switches are designed with the customer and user in mind, so we are confident the enclosure is easy to use, and fits the customers every requirement.

ABS plastic custom enclosures

We create different types of plastic enclosures that range from small and simple to large and complex. With over 10+ years manufacturing using this unique process we have the knowledge and experience to deliver standard plastic enclosures that meet and exceed customer expectations. We manufacture and design customized enclosures according to the client’s design requirements. We work closely with our clients to achieve the most functional and suitable product according to the design specifications needed.

Whether it is for a small enclosure or a large enclosure for your electronic components. CSE TECH has the capability to deliver a quality product to make electronic projects a reality.

For the plastic project boxes, we offer a wide variety of ABS material thicknesses as well as any different size enclosures.

Materials thicknesses variety from 3mm, 4mm, and 6mm.

Our plastic housings usually come in black, white, light grey, or dark grey depends on materials availability.

All plastic enclosures are designed and cut as flat patterns and machined only on one side, this cuts out opposite site machining and cuts back on the cost of labour per item. We are able to add tongues and grooves via sawing and table router to ensure easy assembly. A single qualified person runs multiple machines which guarantees uniformity in workmanship and crafting and also reduces labour expenses. Sheets are cut and milled with precision by Computer Numerical Controlled (CNC) machines with a tolerance of +/- 0.2mm. Tabs are designed to provide rigid holding points during machining and are easily broken out after the product is complete.

A bending table is used to bend and form plastic parts to specific angles or make custom bends for unique custom enclosures. Bends can assist the customer during assembly. The following angles can be achieved: 115° up, maximum standard bend; 45° down, maximum reverse bend; inside bend radius square for 90° bend; 6mm bends tend to warp edges, a 1mm chamfer hides this.

Chamfering and lip edging of plastic parts is available for assembly and completion processes. Chamfers, tongues and grooves can be made. A 0.5mm chamfer on the edge of the tongue can be made to create a cosmetic seam and hide the heat deflection caused at the bend site.

A solvent is used to melt respective pieces together for a seamless finish without compromising strength. By designing the product in such a way as to avoid placing solvent join at a site of high tension.

1K and 2K spray painting

1K and 2K Spray Paint can be done in any colour.

1K paint is less hard-wearing than the 2K alternative. 1K paint is more suitable for items and areas less prone to potential scratches and general wear and tear such as higher cladding panels on a building that do not frequently come into contact with day to day touching and potential damage. 1K paint has a faster drying time compared to 2K paint and will air dry. 1K paints typically dry’s faster than 2K paints.

2K paint provides a harder wearing coat more suitable for surfaces that may come into contact with day-to-day use and heavy access areas. 2K means an activator is required to dry/ cure, sometimes referred to as a hardener. The hardener works by chemically reacting with a catalyst which sets hard to form a very tough finish.

1K and 2K paints have a heat resistant, between 160 – 190 degrees Celsius.

Laser cutting

Laser cutting is a technology that uses a laser to cut materials up to 15mm thick and is typically used for industrial manufacturing applications. Laser cutting works by directing the output of a high-power laser most commonly through optics. Cuts MDF Wood, Acrylics, Cardboard, Foam, Cork, variety of Materials.

Laser engraving

Laser engraving, which is a subset of laser marking, is the practice of using lasers to engrave an object. This is used for etching bar codes onto items or personalising certain items.

Laser marking

This is like engraving in that a mark is made but the difference being that the mark is only surface level, while engraving from laser engraving has much more depth.

Vacuum forming (Thermoforming Principle)

Vacuum forming is a simplified version of thermoforming, where a sheet of plastic is heated to a forming temperature, stretched onto a single surface mold, and forced against the mold by a vacuum. This process can be used to form plastic into permanent objects such as turnpike signs and protective covers.

Forming bed: 200 x 200mm

Draw depth: 130mm

3D printing

3D printing uses computer-aided design (CAD) to create three-dimensional objects through a layering method. Sometimes referred to as additive manufacturing, 3D printing involves layering materials, like plastics, composites or bio-materials to create objects that range in shape, size, rigidity and colour.

* Build volume: 450 x 450 x 470mm

* Filament diameter: 1.75mm

* Compatible filaments: PLA, ABS, PETG, TPU, Wood, Nylon

* Compatible file format: STL, OBJ, AMF

* Printing resolution: 0.1mm

UV printing

Is a unique method of digital printing utilising ultraviolet (UV) light to dry or cure ink, adhesives, or coatings almost as soon as it’s hit the paper, or aluminium, foam board or acrylic – in fact, as long as it fits in the printer, the technique can be used to print on almost anything.

While there are many ways to print, few match UV’s speed-to-market, environmental impact, and colour quality. It cures fast, its high quality, it’s durable and it’s flexible.

Plot 55, Tierpoort, Garsfontein Road (M30)

0056, South Africa

(+27) 81 218 1453 / (+27) 12 006 5061

Home / About us / Services / Gallery / Contact us